Kev ua tau zoo yog lub neej ntawm AISEN.AISEN qhov kev tswj xyuas zoo heev thiab cov qauv khoom zoo tuaj yeem pab cov neeg siv khoom thiab nws cov chaw ua haujlwm txuag nqi thiab sijhawm.

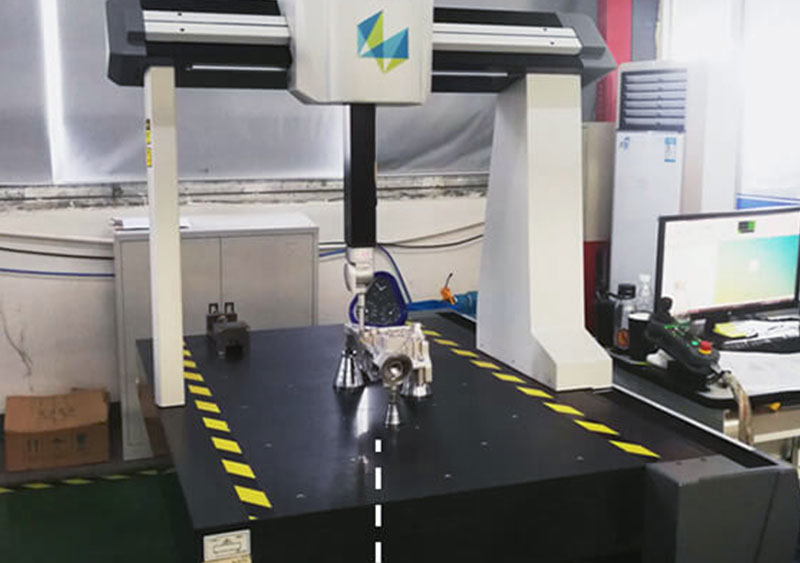

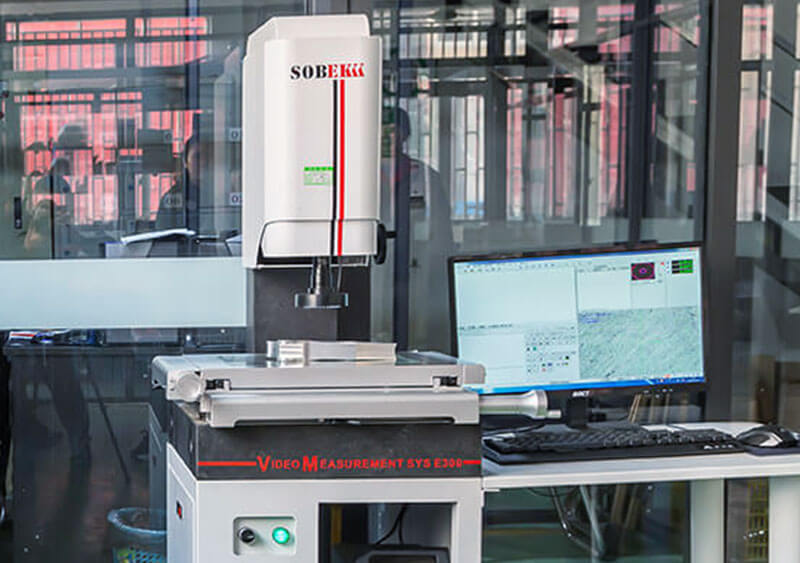

■ Kev soj ntsuam nruj me ntsis thiab ntsuas qhov tseeb ntawm cov qauv

Pab neeg soj ntsuam zoo uas muaj los ntawm AISEN, los ntawm thawj qhov kev sim ntawm lub raj mis yas mus rau kev soj ntsuam ntawm cov qauv sim, yuav tsum dhau los ntawm kev soj ntsuam nruj heev thiab kev tswj xyuas kom zoo kom ntseeg tau tias cov pwm tsim tuaj yeem ua tau raws li cov neeg siv khoom tsim khoom thiab txhaj tshuaj molding.Txhua qhov kev xav tau rau molding.

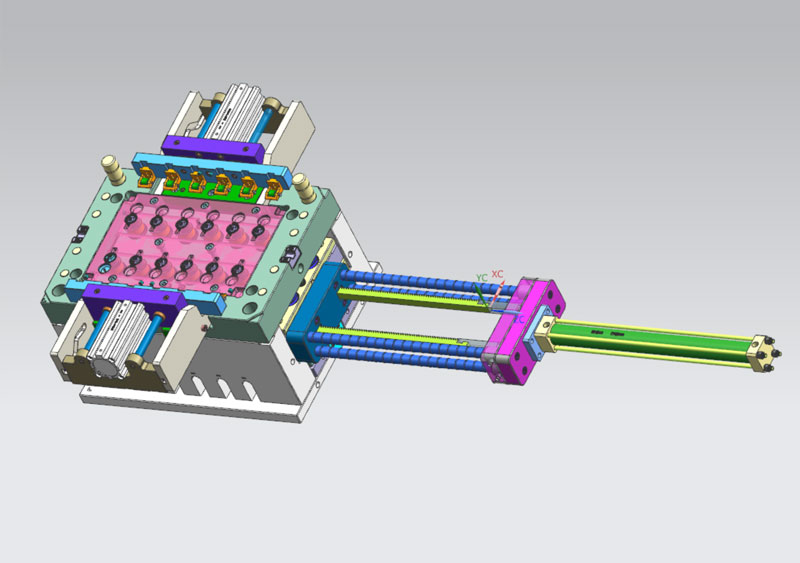

■ 20 xyoo kev paub txog engineers tsim cov duab kos nrog cov cua txias zoo nkauj

■ Cov txheej txheem ua haujlwm siab

Ib txheej zoo ntawm lub raj mis yas pwm stems los ntawm lub tswv yim zoo ntawm AISEN cov neeg rau kev ua tau zoo.

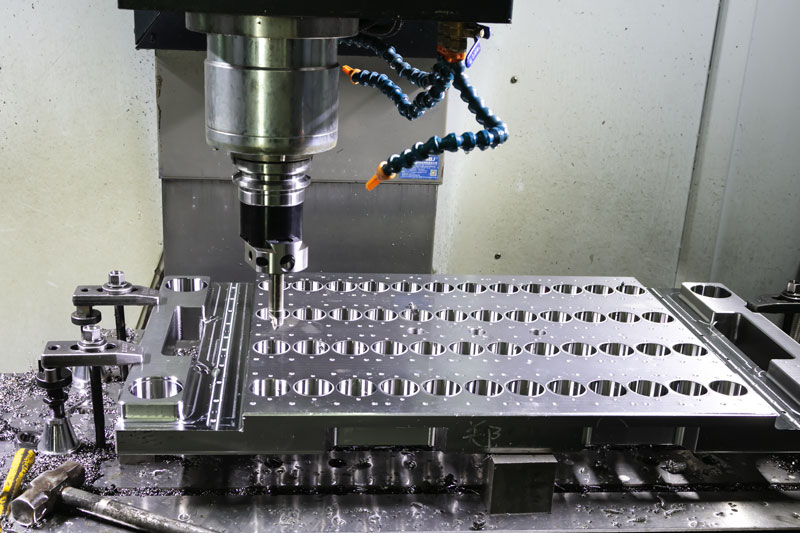

(1) Kev kub ceev CNC tshuab

Kev ruaj khov kom ua tiav "0.1μm pub, 1μm txiav, nm qib roughness"

(2) Ntau CNC machining chaw nrog peb-axis thiab plaub-axis txuas:

ruaj khov rau txheej txheem pwm qhov nyuaj, kom ua tau raws li qhov yuav tsum tau ua ntawm kev ua pwm pwm, tuaj yeem ruaj khov kom ua tiav 10-30μm machining raug.

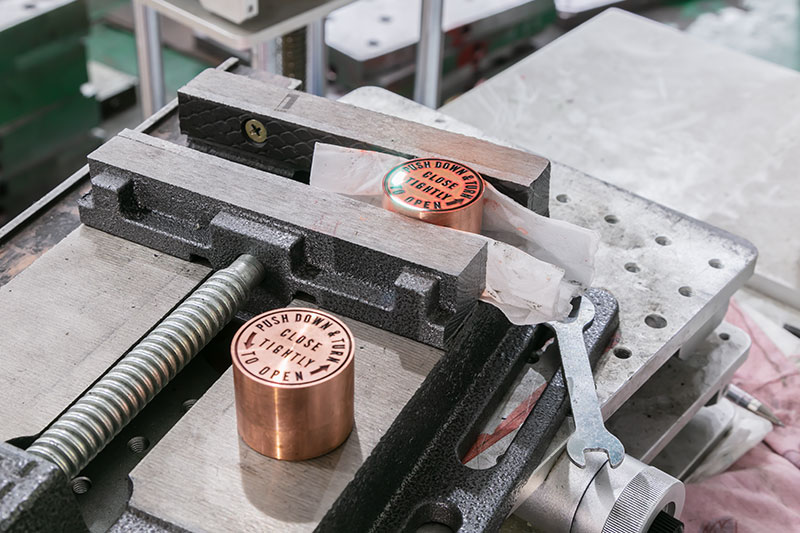

(3) Daim iav Spark tshuab

Cov kws tshaj lij, nruab nrog cov ntaub ntawv siv thev naus laus zis muaj zog, kom ua tiav qhov tseeb (rov ua dua qhov tseeb ≤2μm), kev ua haujlwm siab (≥500mm / min), qhov zoo tshaj plaws nto tiav (RA ≤0.1μm), txuag cov txheej txheem polishing, txhim kho qhov chaw ntawm pwm qhov chaw

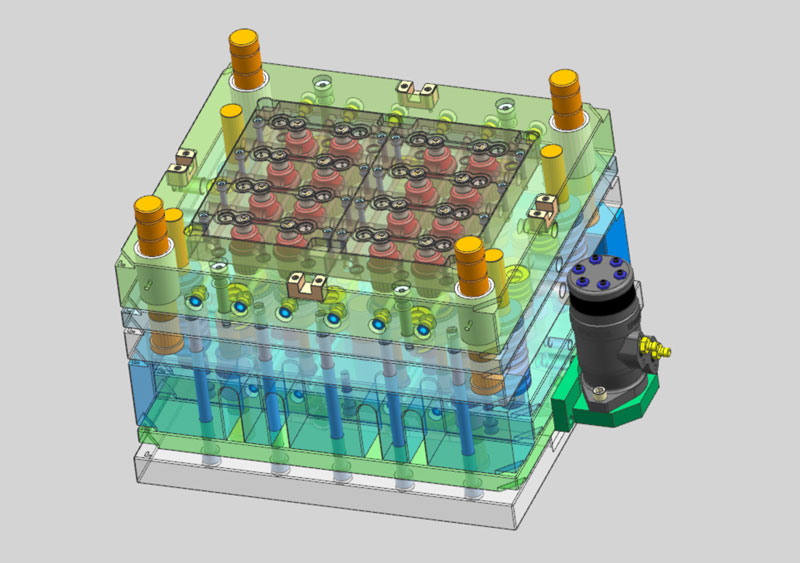

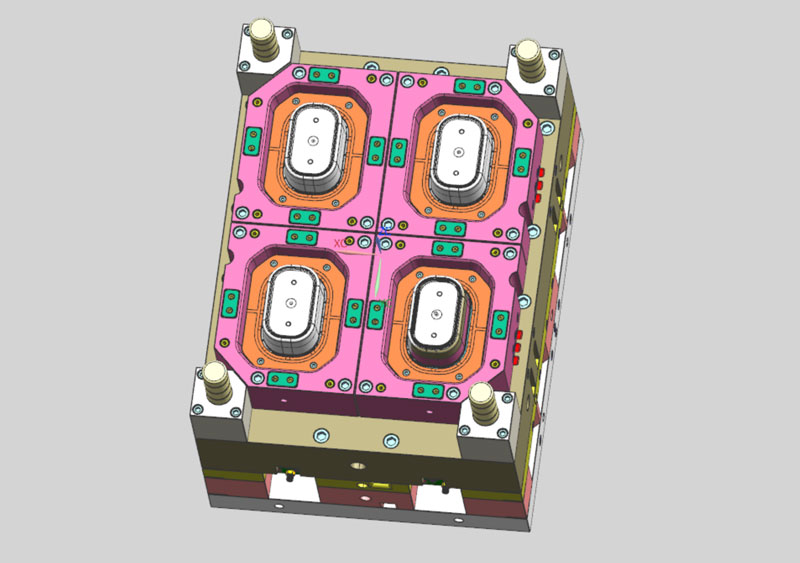

■ Cov txheej txheem ua haujlwm siab

Xaiv qhov tsim nyog kub khiav qhov system tuaj yeem ua kom muaj kev sib npaug thiab ruaj khov ntawm txhua lub rooj vag ntawm cov pwm, thiaj li tsim tau lub hau yas zoo dua.Noj mus rau hauv tus account qhov yooj yim hloov ntawm pwm hais txog accessories nyob rau hauv lub tom ntej no lub sij hawm, Peb muaj peev xwm muab ntau yam hom ntawm kub runners rau cov neeg muas zaub xaiv.